Our Technology

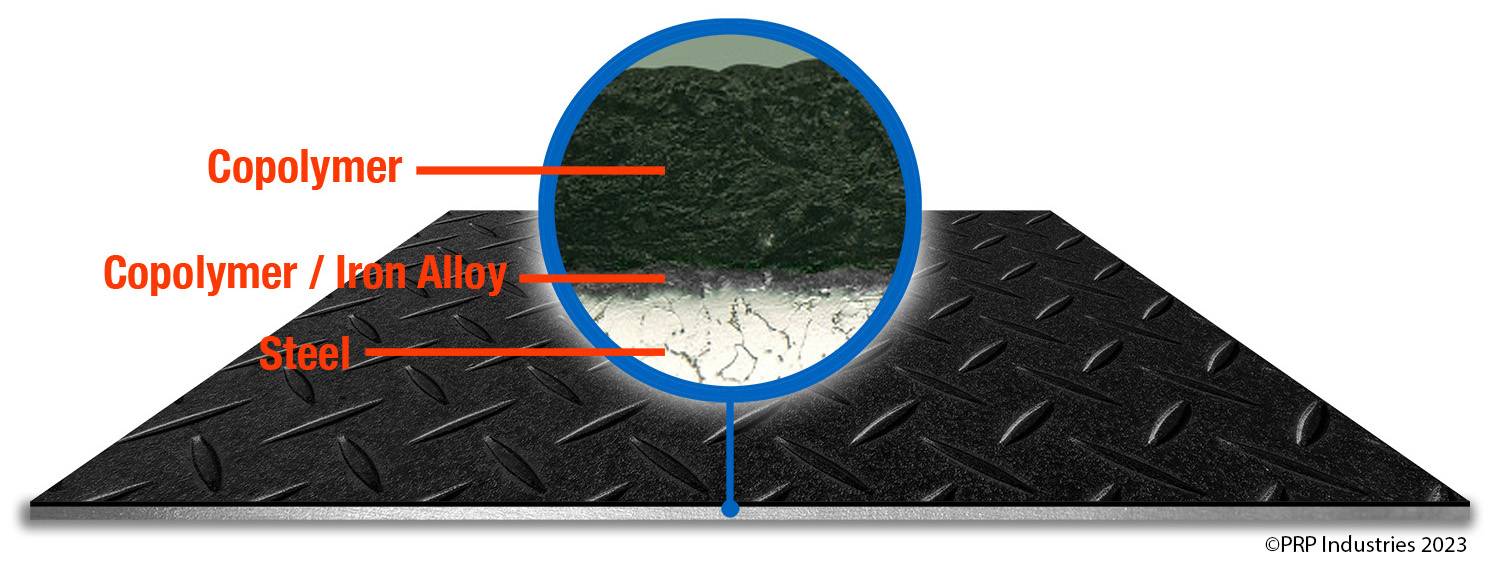

CORSOL® corrosion solutions are the ONLY long-term, field-proven solutions with decades of documented proof. CORSOL® corrosion solutions protection is derived from a process called METAL POLYMERIZATION® in which an appropriate proprietary liquid copolymer is applied to a metallic surface. A chemical reaction occurs between the copolymer and the metallic substrate, creating a copolymer iron alloy layer that fuses the copolymer and steel. This layer creates non-sacrificial protection against corrosion undercutting and blistering.

CORSOL® corrosion solutions

Cross-Section

THE ALTERNATIVE TO GALVANIZING®

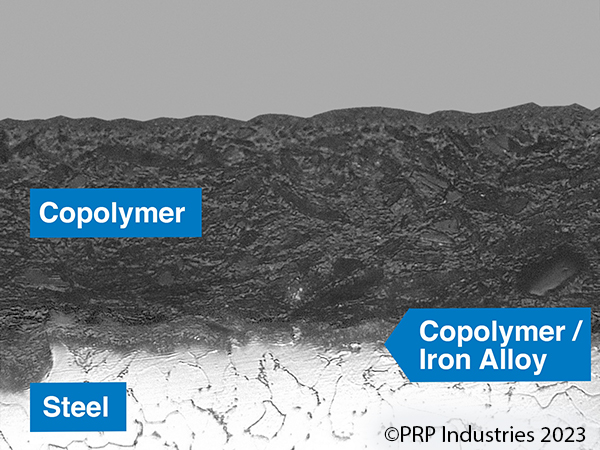

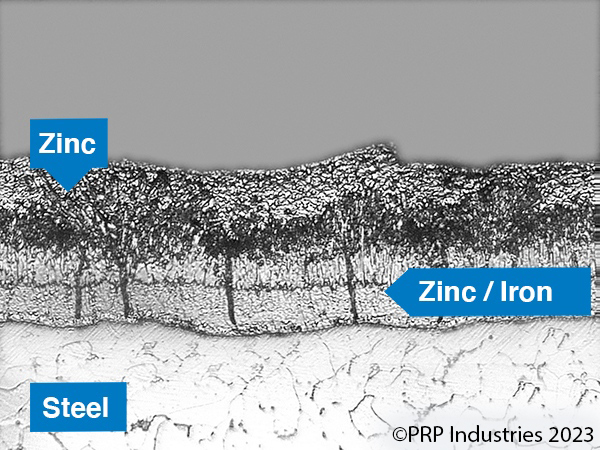

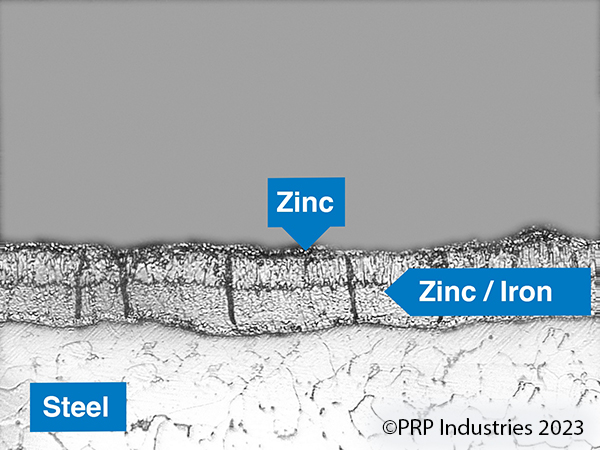

Numerous manufacturers utilize PRP’s METAL POLYMERIZATION® process as a replacement to Hot-Dip Galvanizing. The plate below shows a comparison between the two technologies.

METAL POLYMERIZATION®

(steel plate)

actual cross-section microimage

Hot-Dip Galvanizing

(steel plate)

actual cross-section microimage

Hot-Dip Galvanizing

(steel plate)

after six years of zinc depletion

simulated cross-section microimage